IBK-fibertec – GRP. Worldwide.

With our products, services and qualities, we have become an internationally active market leader for GRP antenna cylinders and GRP mobile phone masts.

Our products

Aerial cylinders, mobile phone masts and lightweight structures made of glass-reinforced plastic (GRP).

Our qualities

- 40 years of experience with GRP

- Entirely customer-focused

- Intelligence, innovation and integrity

Our performance

- Planning

- Calculation

- Conception

- Production

Portfolio

Structural components

Rotor blades of wind turbines are now too large to be transported over roads to construction sites...

Antenna cylinders

Professional antenna systems are installed all over the world on high transmitter masts and towers...

Mobile phone masts

For three key reasons, GRP for mobile phone masts is the optimal alternative to steel and reinforced concrete...

Support towers and overhead wires

IBK has developed and manufactured a fiberglass support tower for its partner...

Special components

The application of fiber-composite technology has made extraordinary progress in recent decades...

Engineering and design

We support our customers during the phases of planning, design and production...

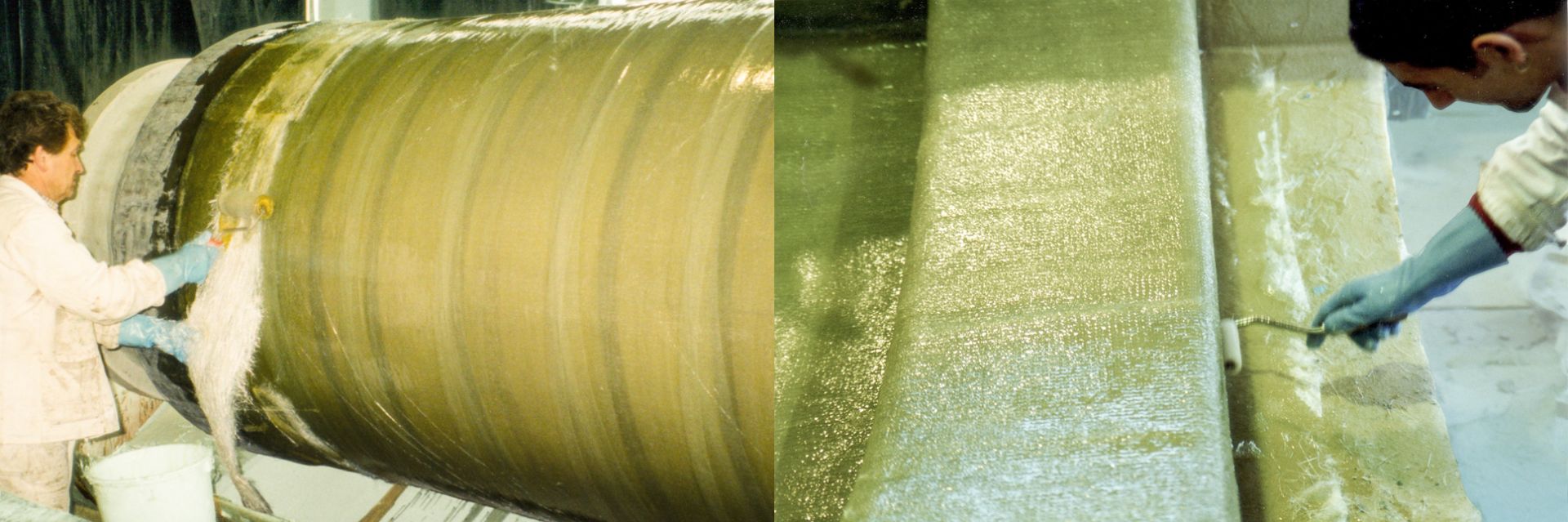

Manufacturing process

The company IBK-Fibertec –

development, production and consulting

The nucleus of IBK-Fibertec was the IBK Ingenieur-Büro für Kunststofftechnik GmbH. Under Bernd Burgwedel and Harald Westrup, all areas were decisively developed and expanded. The company is headquartered in Büren in North Rhine-Westphalia, Germany.

Today, IBK-Fibertec is an independent, family-owned limited company known worldwide for its leadership position in the international GRP market, with customers from more than 22 countries.

The company’s services include consulting, planning, design and the manufacturing of fiber-composite products.

The access to 40 years of experience with the material GRP forms the basis today for high-quality production and the permanent development of innovative and intelligent lightweight products.

Past projects

|

Year |

Location |

Height/m |

|

2003 |

Colonius |

14.10 |

|

2004 |

Braunschweig 3 |

26.80 |

|

2004 |

Dortmund 3-II |

19.20 |

|

2004 |

Essen |

19.20 |

|

2004 |

Wesel II |

19.20 |

|

2004 |

Düsseldorf 10 |

19.20 |

|

2004 |

Frankfurt |

19.20 |

|

2004 |

Hamburg 22 |

24.05 |

|

2004 |

Kiel |

12.50 |

|

2004 |

Münster-Nottuln |

16.50 |

|

2004 |

München Olympiaturm |

19.20 |

|

2004 |

Wendelstein |

23.10 |

|

2004 |

Nürnberg 5 |

14.30 |

|

2005 |

Stuttgart-Frauenkopf |

19.20 |

|

2005 |

Heidelstein-Rhön |

17.20 |

|

2005 |

Bielstein-Teutoburgerwald |

21.52 |

|

2006 |

Hoher Bogen |

23.10 |

|

2006 |

Brotjacklriegl |

23.10 |

|

2006 |

Booßen |

10.30 |

|

2007 |

Münster 42 |

6.50 |

|

2007 |

Schöneck |

10.30 |

|

Year |

Location |

Height/m |

|

2007 |

Löbau |

15.00 |

|

2007 |

Vogtsburg-Freiburg |

12.70 |

|

2007 |

Grünten |

23.60 |

|

2007 |

Donnersberg |

18.80 |

|

2007 |

Brocken |

15.00 |

|

2007 |

Hohenpeissenberg |

12.70 |

|

2007 |

Donaueschingen |

13.00 |

|

2007 |

Ravensburg |

15.00 |

|

2007 |

Ulm |

15.30 |

|

2008 |

Pfaffenberg |

17.10 |

|

2008 |

Ochsenkopf |

24.00 |

|

2008 |

Koblenz-Kühkopf |

30.00 |

|

2008 |

Ahrweiler |

8.10 |

|

2008 |

Bad Marienberg |

12.30 |

|

2008 |

Dequede |

18.30 |

|

2008 |

Waldenburg |

14.30 |

|

2008 |

Aalen / Braunenberg |

14.30 |

|

2008 |

Pforzheim-Langenbrand |

15.00 |

|

2008 |

Amberg-Hirschau |

|

|

2008 |

Bamberg-Buttenheim |

12.80 |

|

2009 |

Hamburg-Höltigbaum |

|

Contact

IBK-Fibertec GmbH

Westring 40

D-33142 Büren

Telephone +49 2951 93988-0

Telefax +49 2951 93988-22

E-Mail info@ibk-fibertec.de